Why Quality Flow Components Matter in Heavy Industries

In heavy industries, the smallest parts can make the biggest difference. Flow components such as valves, fittings, and control parts are the backbone of fluid systems used in power plants, petrochemicals, mining, and large-scale manufacturing. When chosen wisely, these components deliver not just performance but also long-term reliability in industrial systems. This blog explores why quality flow components are vital, what features to look for, and how they impact efficiency, safety, and costs in demanding environments.

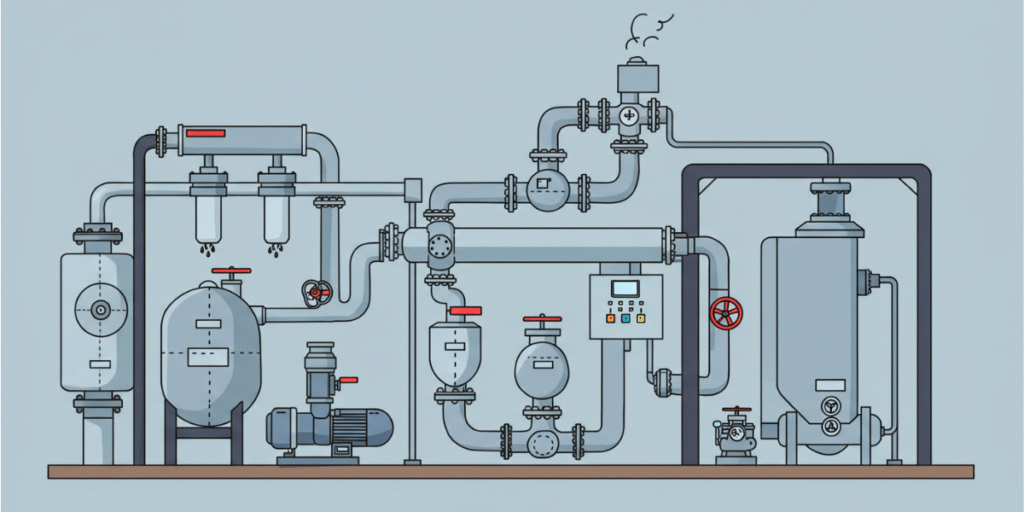

The Role of Flow Components in Industrial Operations

Flow components are more than just connectors and regulators for manufacturing. They determine how fluids, gases, and chemicals are managed within industrial systems. A small fault in a valve or fitting can cause leaks, pressure imbalance, or a complete system shutdown.

Key responsibilities of flow components include:

- Maintaining fluid pressure levels.

- Controlling the direction and volume of flow.

- Preventing contamination between fluids.

- Supporting safe operation under extreme conditions.

Without precision flow control parts, industrial processes would lack accuracy, stability, and efficiency.

Why High-Performance Flow Equipment Matters

In heavy industries, systems operate under extreme pressure, temperature, and environmental stress. This makes high-performance flow equipment critical. Durable components reduce the risk of failures that could disrupt production or compromise safety.

Quality flow equipment is designed with advanced materials, such as stainless steel alloys and corrosion-resistant coatings, to withstand aggressive chemicals or abrasive particles. The focus is not just on durability but also on maintaining consistent performance over the years of operation. When industries invest in high-performance flow equipment, they gain operational stability and improved safety standards.

Reducing Downtime in Heavy Industries

Downtime is costly in any industry, but in heavy industries, the losses multiply quickly. Equipment stoppages can halt entire production lines, delay deliveries, and increase labor costs. Poor-quality flow components often contribute to this problem through unexpected leaks, pressure failures, or premature wear.

Reliable components play a major role in reducing downtime in heavy industries by:

- Extending maintenance cycles.

- Providing consistent operation under stress.

- Reducing the likelihood of emergency shutdowns.

- Supporting predictive maintenance systems with accurate performance data.

Every hour saved through reliable components translates into significant cost savings for businesses.

Precision Flow Control Parts: Supporting Accuracy and Safety

Precision is not optional in heavy industries; it is mandatory. Precision flow control parts are engineered to regulate flow rates with extreme accuracy. In applications such as chemical mixing, gas distribution, or power generation, even a minor imbalance can affect the final product or lead to safety hazards.

High-precision components support accurate dosing, stable fluid distribution, and safer operations by minimizing risks of leaks or over-pressurization. They improve output quality, reduce defects, and help industries achieve operational excellence while meeting regulatory compliance standards effectively.

Reliability in Industrial Systems: A Long-Term Advantage

Industrial systems are complex networks of interconnected machinery, and each part must perform without failure. Reliability in industrial systems depends on the quality of every flow component used. A single defective part can compromise the entire system, leading to unplanned maintenance and safety risks.

Reliable flow components strengthen system resilience, reduce performance fluctuations, and support consistent productivity in demanding environments. They provide long-term confidence for 24/7 operations, making reliability in industrial systems a vital strategic advantage for globally competitive businesses.

Industrial Fluid Management Solutions: The Bigger Picture

Managing fluids in heavy industries is about more than just moving liquids or gases. It involves precision, safety, and efficiency across entire systems. Industrial fluid management solutions include pumps, valves, fittings, flow meters, and monitoring systems that work together to optimize operations.

A complete solution offers balanced fluid distribution, integrated performance monitoring, easier maintenance with standardized parts, and compatibility with automation for smarter operations. By investing in comprehensive industrial fluid management solutions, companies reduce risks, cut costs, and achieve stronger overall output.

Choosing the Right Flow Components

Selecting flow components requires careful evaluation. Industries should focus on:

- Material Strength: Components should withstand the specific fluids and conditions involved.

- Performance Ratings: Flow, pressure, and temperature specifications must meet system requirements.

- Manufacturer Reputation: Established brands with proven records typically offer better reliability.

- Compatibility: Components should integrate seamlessly with existing equipment.

- Maintenance Support: Easy-to-source replacements and service support extend tool life.

Investing time in selection upfront prevents long-term problems and supports smoother operations.

Common Mistakes When Purchasing Flow Equipment

Many companies struggle with recurring issues because of poor equipment choices. Common mistakes include:

- Choosing lower-cost options over proven performance.

- Overlooking chemical compatibility with materials.

- Ignoring certifications and compliance requirements.

- Failing to evaluate supplier reliability.

These mistakes often lead to premature failures, unexpected downtime, and higher replacement costs. Avoiding them is key to building stronger industrial systems.

How Technology is Improving Flow Components

Modern advancements are reshaping the world of flow equipment. Today’s high-performance flow equipment incorporates smart sensors, IoT connectivity, and advanced coatings to improve efficiency and longevity. These innovations support predictive maintenance, helping industries identify problems before they cause disruptions.

Automation integration also means precision flow control parts can now be monitored and adjusted remotely. This provides greater accuracy, improved safety, and higher levels of productivity in heavy industries.

Balancing Cost and Long-Term Value

It’s tempting to cut costs on components that appear minor in the overall system. However, quality flow equipment should be seen as a long-term investment. While premium products may require higher upfront spending, the savings gained from reducing downtime, extending maintenance intervals, and improving safety often outweigh initial costs.

Long-term value should always guide purchasing decisions, especially in industries where reliability directly impacts revenue.

Building a Reliable Flow Strategy

A strategic approach to flow management goes beyond choosing durable components. It includes routine system assessments, predictive maintenance, staff training on early warning signs, and working with trusted suppliers. This system-wide strategy strengthens operational stability and builds confidence in meeting production demands.

Summing It Up

Heavy industries rely on consistency, efficiency, safety, and quality, and flow components are central to achieving them. By investing in high-performance flow equipment, precision control parts, and advanced fluid management solutions, businesses gain measurable improvements across operations.

Looking for dependable flow components for your manufacturing industry? Industrial Supply Groups stands out as one of the top industrial equipment exporters to Saudi Arabia, providing tailored solutions, premium-quality components, and trusted support to keep your operations running efficiently.

FAQs: Why Quality Flow Components Matter in Heavy Industries

What are flow components in heavy industries?

Flow components include valves, pumps, hoses, fittings, regulators, and other parts that control the movement of liquids, gases, or chemicals within industrial systems.

Why is the quality of flow components so important?

High-quality components ensure reliable performance, reduce downtime, enhance safety, and prevent costly failures in high-pressure or high-temperature environments.

How do low-quality flow components affect heavy industries?

Poor-quality components can lead to leaks, contamination, inefficiency, frequent breakdowns, and safety hazards, which can disrupt operations and increase maintenance costs.

Which industries rely most on quality flow components?

Industries such as oil and gas, chemical processing, power generation, water treatment, and manufacturing depend heavily on durable and precise flow control systems.

How do quality flow components improve workplace safety?

They minimize risks of leaks, pressure surges, or equipment failures that can cause fires, explosions, or chemical exposure in hazardous industrial settings.

Are certified flow components necessary for compliance?

Yes. Many industries require ISO, ANSI, API, or OSHA-certified components to meet safety and regulatory compliance standards.

Do high-quality flow components reduce long-term costs?

Absolutely. Although they may cost more upfront, quality components lower repair, replacement, and downtime expenses, leading to better long-term value.

How can I identify a reliable supplier of flow components?

Look for suppliers with proven industry experience, certifications, strong after-sales support, and partnerships with trusted global brands.

What role does material quality play in flow components?

Materials such as stainless steel, high-grade alloys, and reinforced polymers offer durability, corrosion resistance, and performance under extreme conditions.

How does innovation impact flow component performance?

Advanced designs with smart sensors, automation compatibility, and energy-efficient features enhance productivity and system monitoring in heavy industries.