How Industrial Valves Are Powering Saudi Arabia’s Oil & Gas Sector

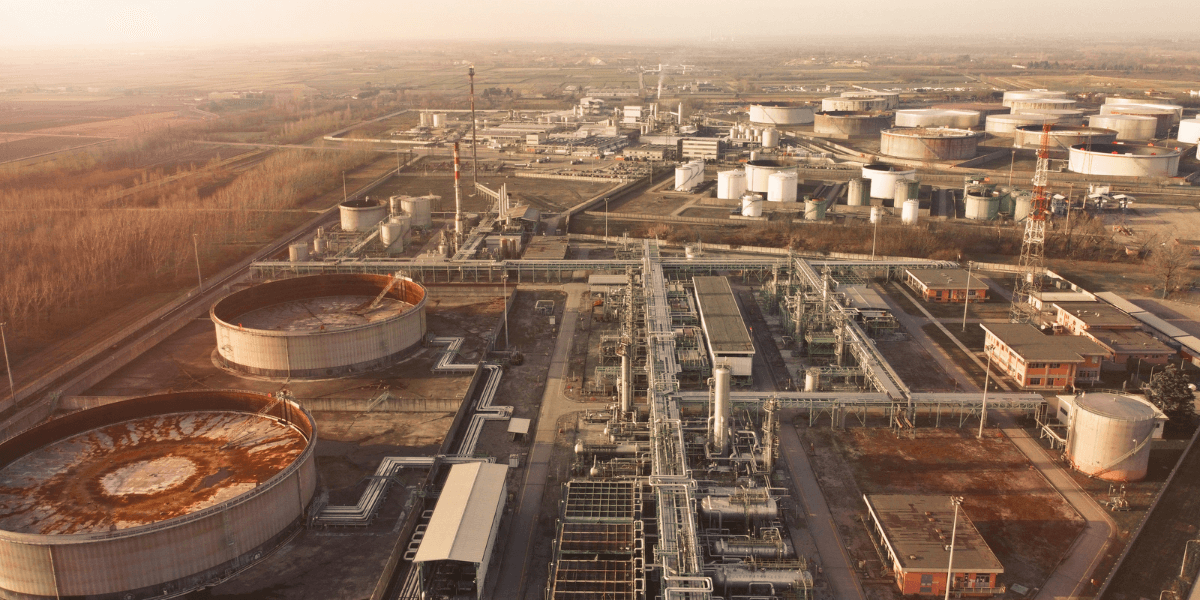

Saudi Arabia’s oil and gas industry is one of the most advanced and strategic in the world. With vast energy reserves and world-leading production capabilities, the Kingdom plays a vital role in keeping the global energy market balanced and stable. Behind the massive pipelines, offshore rigs, and inland refineries, there is a world of engineering detail making everything work. One of the unsung heroes of this entire ecosystem is the industrial valve.

These devices might be small compared to a drilling rig or refinery tower, but they hold enormous importance. Without the right valves, there would be no precision, no safety, and no efficiency. From managing high-pressure steam to regulating chemical flows, industrial valves are at the very heart of how Saudi Arabia powers its oil and gas sector.

Let’s take a look at the role these valves play and why they are more critical than ever before.

Controlling the Flow in Complex Operations

At its core, oil, and gas production is about controlling the flow of different materials. From crude oil deep underground to natural gas passing through kilometers of pipeline, movement has to be measured and managed with total precision. This is exactly what industrial valves are designed for.

When it comes to flow control solutions for oil rigs, it’s not just about turning a valve on or off. It’s about regulating pressure, managing multiple inputs, and ensuring that systems remain stable even under extreme conditions. On offshore rigs, this becomes even more important. These environments are exposed to saltwater, wind, and heavy loads, which makes durability just as important as functionality.

Modern valves are engineered to be intelligent. Many are now fitted with actuators and smart sensors that allow remote operation and diagnostics. This allows operators to monitor systems in real time and take action before problems grow.

Innovation in Upstream Valve Technology

As Saudi Arabia continues to invest in upstream operations, valve technology is evolving right alongside it. The upstream valve technology Saudi market is growing fast, fuelled by the need for more resilient, high-performance components that can handle corrosive fluids, high temperatures, and pressure variations.

Drilling and extraction processes have become more demanding. Companies now need valves that can handle sour gas, abrasive sand mixtures, and thermal cycling without losing performance. As a result, manufacturers are developing advanced sealing mechanisms, exotic alloys, and coatings that extend the life of valves while maintaining precise control.

These upstream technologies are critical for maintaining safety and operational efficiency. A single faulty valve in a wellhead or pipeline system can lead to shutdowns, environmental incidents, or worse. This is why the Saudi energy sector is placing a stronger emphasis on quality control and lifecycle management of valves used in the upstream phase.

Selecting the Right Valve for Harsh Environments

Saudi oilfields are not your average work site. They involve some of the most demanding operational conditions on the planet. From the heat of the desert to the pressure at thousands of feet below the surface, materials, and components have to be exceptionally tough.

That’s where valve selection for harsh oilfield environments becomes a make-or-break decision. Engineers need to consider factors like fluid type, temperature range, pressure limits, and the physical layout of the site. Some environments require ball valves, others need gate valves or pressure-reducing valves. One wrong choice can result in reduced efficiency, maintenance challenges, or safety risks.

The good news is that Saudi Arabia has developed a strong understanding of these needs over the years. Local suppliers and field service teams are trained to match each application with the right valve solution, reducing the chance of failure and extending operational life.

Keeping Saudi Refineries Running Smoothly

Once crude oil is extracted, the journey is far from over. It moves to refineries where it is transformed into usable products like gasoline, diesel, petrochemicals, and jet fuel. This is another area where valves play a crucial role.

Saudi oil refineries valve systems must be robust, fast-acting, and capable of managing multiple process stages with high reliability. These include separation, cracking, distillation, and treatment processes, all of which depend on fluid movement being accurately managed. Valves used here must also be resistant to chemical corrosion and have tight sealing properties to avoid leakage.

Saudi Arabia’s mega-refineries are among the most advanced in the world. They rely on thousands of valves working in coordination to achieve precise outcomes at massive scales. It’s not just about flow anymore. It’s about process control, automation, and energy efficiency, all of which require finely tuned valve systems.

Strengthening the Local Supply Chain

Behind the scenes of this high-tech industry lies a network of suppliers, distributors, and service providers. The oil and gas valve supply chain in Saudi Arabia is critical to maintaining the uptime and performance of operations across the Kingdom.

This supply chain includes everything from international manufacturers to local stocking partners and emergency maintenance providers. With energy security and national growth at stake, Saudi Arabia has invested in developing a more self-reliant and responsive valve supply network.

Domestic assembly plants, quality control labs, and fast-response maintenance units have all been established to meet the growing needs of the industry. Having local access to the right valves and the people who understand how to install and maintain them reduces downtime and improves safety.

This also fits into Saudi Arabia’s wider industrial strategy, which aims to localize more of the supply chain and reduce dependency on imports. It’s a move that not only boosts job creation but also builds long-term resilience in a sector that simply cannot afford to slow down.

Conclusion

The success of Saudi Arabia’s oil and gas sector is built on more than just resource availability. It depends on the invisible yet essential components that make the system work. Industrial valves are one of those components. They control flow, maintain safety, boost efficiency, and ensure that everything runs like clockwork.

The Kingdom is pushing forward with smarter, more durable valve systems. Careful valve selection for harsh oilfield environments and world-class Saudi oil refineries’ valve systems ensure every phase of oil production meets the highest standards. And a resilient oil and gas valve supply chain ties it all together.

Saudi Arabia’s energy future depends on many things, but without a doubt, the humble valve is one of its most powerful tools. Looking for the right partner to keep your oilfield operations running smoothly? Industrial Supply Groups is your go-to heavy equipment supplier and trusted oilfield supply company for Saudi Arabia. With top-tier valve solutions, on-time delivery, and expert technical support, we help you get the job done right. Let’s move your project forward together. Reach out today.