The Role of AI and IoT in Streamlining Industrial Processes

In today’s rapidly evolving industrial landscape, the integration of Artificial Intelligence (AI) and the Internet of Things (IoT) is revolutionizing manufacturing processes. These technologies are enhancing efficiency, reducing downtime, and enabling predictive maintenance, thereby transforming traditional manufacturing into smart, connected operations.

Embracing AI in Industrial Automation

AI in industrial automation is transforming manufacturing by allowing machines to perform complex tasks with less human intervention. Through machine learning algorithms, AI systems can analyze vast amounts of data to optimize production schedules, detect anomalies, and improve quality control. This results in higher productivity and lower operational costs. By automating routine tasks, AI allows human workers to focus on more strategic activities, fostering innovation and efficiency in the industrial sector.

Leveraging IoT in Manufacturing

The implementation of IoT in manufacturing involves embedding sensors and devices into machinery and equipment to collect real-time data. This data provides insights into machine performance, energy consumption, and environmental conditions, enabling manufacturers to make informed decisions. IoT facilitates remote monitoring, predictive maintenance, and inventory management, leading to streamlined operations and reduced downtime. By connecting various components of the manufacturing process, IoT creates a cohesive and responsive production environment.

Implementing Predictive Maintenance Using AI

Predictive maintenance using AI involves analyzing data from sensors and equipment to predict potential failures before they occur. By identifying patterns and anomalies, AI systems can schedule maintenance activities proactively, minimizing unplanned downtime and extending equipment lifespan. This approach reduces maintenance costs and enhances safety and reliability in manufacturing operations. Predictive maintenance ensures that machinery operates at optimal efficiency, contributing to overall productivity.

Utilizing Real-Time Data in Industrial Systems

Access to real-time data in industrial systems is crucial for making timely and informed decisions that can significantly impact operational efficiency. Real-time monitoring enables manufacturers to track production metrics closely, facilitating the early detection of issues and allowing for swift responses to changing conditions on the shop floor. This immediacy enhances overall operational agility, improves product quality, and helps reduce waste throughout the production process. Moreover, by leveraging real-time data, industrial systems can continuously adapt to dynamic environments, ensuring consistent performance and maintaining competitiveness in an ever-evolving market. Ultimately, this capability empowers organizations to optimize their resources and drive sustainable growth.

Integrating AI and IoT

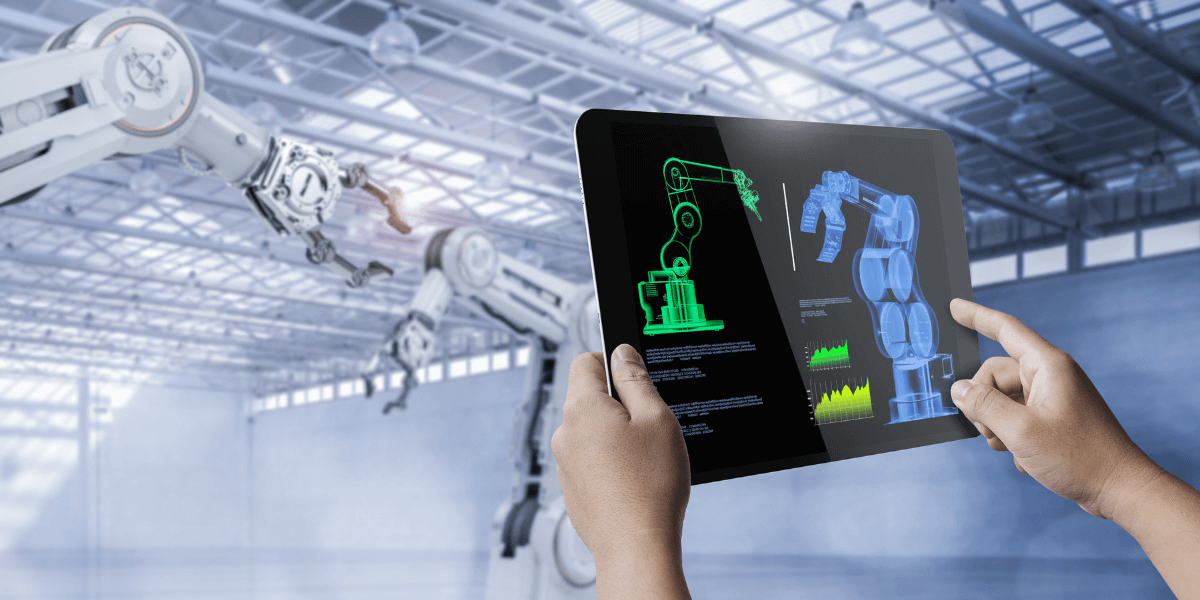

The integration of AI with IoT results in intelligent systems that can make autonomous decisions and adapt responses. AI processes the data collected by IoT devices to optimize operations, predict maintenance needs, and enhance product quality. This synergy enables a more responsive and efficient manufacturing process, where systems can learn from data patterns and adjust accordingly. Integrating AI and IoT is a cornerstone of the smart factory concept, driving innovation and operational excellence.

Enhancing Quality Control with AI and IoT

Combining AI and IoT technologies significantly enhances quality control in manufacturing processes, particularly for construction companies in Saudi Arabia, like Industrial Supply Groups. IoT sensors are deployed throughout production lines to continuously monitor key parameters, such as temperature, pressure, and humidity. These sensors gather vast amounts of data, which AI algorithms analyze in real time to detect any deviations or defects. This proactive approach enables construction companies to implement immediate corrective actions, significantly reducing scrap rates and ensuring consistent product quality. Moreover, with enhanced quality control, these companies can streamline operations, minimize downtime, and ultimately increase customer satisfaction. Additionally, adhering to industry standards becomes more manageable, fostering a better reputation and facilitating compliance with regulatory requirements in the competitive Saudi Arabian market.

Optimizing Supply Chain Management

AI and IoT play a vital role in optimizing supply chain management by providing enhanced visibility and predictive insights. IoT devices, including sensors and RFID tags, monitor inventory levels, shipment statuses, and environmental conditions in real time. This data is then analyzed by AI algorithms to forecast demand, identify trends, and optimize logistics operations. Such integration effectively reduces delays, minimizes excess inventory costs, and enhances overall supply chain efficiency. By leveraging these advanced technologies, businesses can ensure timely delivery and greater responsiveness to market demands, ultimately leading to improved customer satisfaction and a competitive advantage in the marketplace.

Improving Energy Efficiency

Energy efficiency is a critical concern in manufacturing, and AI and IoT technologies offer effective solutions. IoT sensors track energy usage patterns, while AI algorithms find ways to save energy by optimizing the use of equipment and production schedules. Implementing these technologies leads to reduced energy costs, lower carbon emissions, and compliance with environmental regulations. Operations that use energy efficiently support sustainable manufacturing practices.

Facilitating Remote Monitoring and Control

Integrating AI and IoT significantly enhances the efficiency of manufacturing processes by enabling remote monitoring and control. Operators can access real-time data and manage systems from virtually any location, which increases flexibility and responsiveness to changing conditions. This capability is especially valuable for managing multiple facilities or during times when on-site presence is restricted, such as during emergencies or pandemics. Remote monitoring provides constant supervision, facilitating prompt problem-solving and reducing downtime. Ultimately, these advancements contribute to uninterrupted production processes, reducing operational risks and improving overall productivity in the manufacturing sector.

Supporting Workforce Development

The adoption of AI and IoT in manufacturing requires developing the workforce to provide employees with essential skills. Training programs focused on data analysis, system integration, and digital tools are essential for a smooth transition. By investing in workforce development, companies ensure that their employees can effectively operate and maintain advanced technologies, leading to increased job satisfaction and retention. A skilled workforce is integral to the successful implementation of AI and IoT solutions.

Final Words

The integration of AI and IoT is revolutionizing industrial manufacturing by improving efficiency, minimizing downtime, and facilitating proactive maintenance. These technologies offer real-time insights, streamline operations, and promote sustainability practices. As the industry continues to evolve, embracing AI and IoT will be crucial for maintaining competitiveness and meeting the demands of a dynamic market. Investing in these technologies and workforce development will position manufacturers and industrial suppliers in Saudi Arabia, such as Industrial Supply Groups, for long-term success in the era of smart manufacturing.